Unveiling a Comprehensive Option of Sturdy Undercarriage Parts for Heavy Machinery

Wiki Article

Make The Most Of Efficiency With Long Lasting Undercarriage Parts

In the world of heavy machinery and tools, the function of undercarriage components is vital in ensuring optimum performance and long life. The performance and efficiency of these components can dramatically influence the total operation of equipment, making the choice of durable undercarriage parts a critical decision for supervisors and operators alike. By checking out the detailed connection in between longevity and performance in undercarriage parts, a much deeper understanding of the subject emerges, clarifying the crucial elements that drive operational success. As we browse with the intricacies of undercarriage element, upkeep, and longevity option, a comprehensive expedition awaits to introduce the crucial strategies for accomplishing peak efficiency in sturdy applications.Benefits of Utilizing Long Lasting Undercarriage Parts

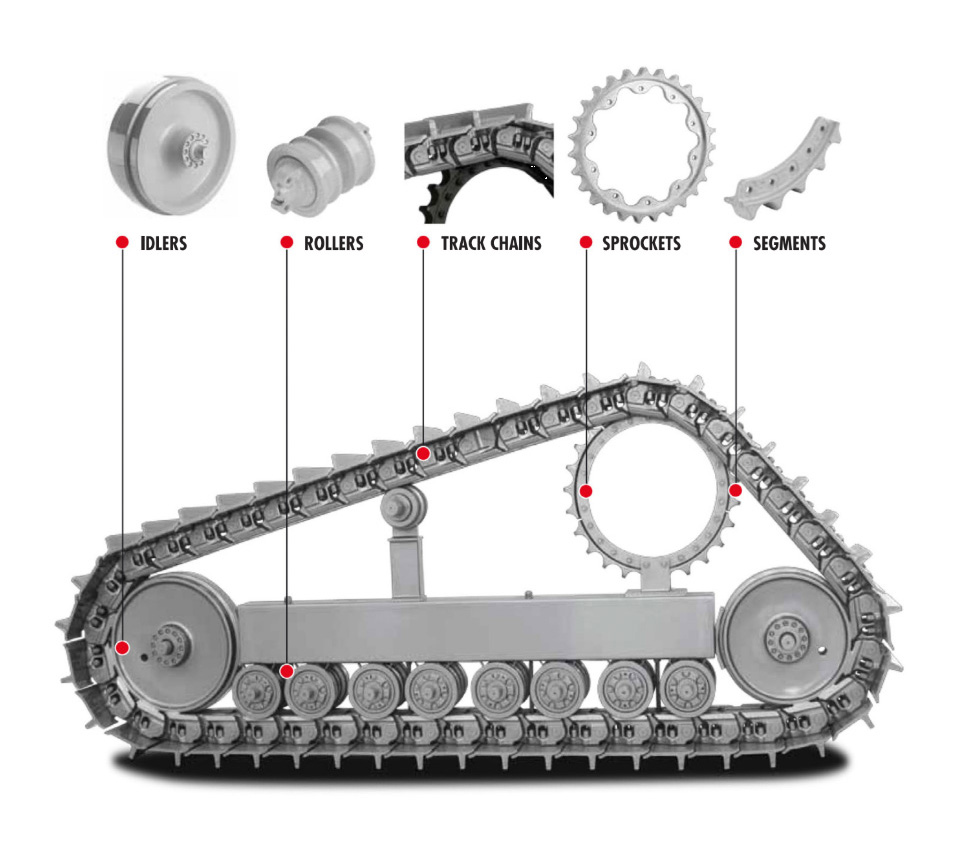

Utilizing resilient undercarriage parts not only enhances the longevity of hefty equipment but also minimizes maintenance prices significantly. By purchasing premium undercarriage elements, such as tracks, sprockets, idlers, and rollers, equipment operators can experience raised uptime and enhanced total efficiency.

In addition, the longevity of heavy equipment is straight linked to the top quality of its undercarriage parts. Long lasting parts can withstand the rigors of demanding applications, making sure that the devices continues to be operational for extended periods. Consequently, drivers can prevent pricey downtime and maintenance costs, inevitably optimizing the return on investment for their machinery.

Factors Impacting Undercarriage Toughness

The durability of undercarriage parts in hefty equipment is influenced by numerous vital aspects that directly effect performance and longevity. Top notch materials, such as hardened steel, are crucial for standing up to the severe conditions and heavy loads that undercarriage parts are subjected to - undercarriage parts.Furthermore, environmental factors can have a significant impact on the long life of undercarriage components. Direct exposure to unpleasant products, severe temperatures, and rough working problems can increase deterioration on undercarriage parts. For that reason, choosing undercarriage components that are especially developed to withstand these environmental obstacles is essential for guaranteeing resilience.

In addition, the style and engineering of undercarriage parts have a straight impact on their resilience. Parts that are made to disperse lots equally, reduce rubbing, and decrease stress and anxiety focus are more probable to have a much longer lifespan - undercarriage parts. By thinking about these crucial elements, tools drivers can make the most of the toughness and performance of their undercarriage elements

Maintenance Tips for Prolonging Undercarriage Life

Carrying out regular maintenance routines is essential for extending the life expectancy of undercarriage elements in hefty equipment. Furthermore, guarantee her comment is here that the undercarriage is correctly lubed according to maker guidelines to minimize friction and stop early wear.One more essential upkeep idea is to maintain the undercarriage clean from dust, rocks, and debris. Build-up in the undercarriage can speed up wear and rust, causing expensive fixings. Cleaning the undercarriage after procedure in harsh problems is recommended to stop these issues.

Last but not least, tracking and recording maintenance activities can help in creating an aggressive maintenance timetable. Maintaining detailed documents of repairs, examinations, and replacements can offer important insights into the undercarriage's problem and performance in time, assisting in predicting and stopping potential failings. By adhering to these maintenance ideas vigilantly, drivers can considerably enhance the toughness and efficiency of undercarriage parts in hefty equipment.

Picking the Right Undercarriage Elements

Choosing ideal undercarriage parts is vital for making best use of the effectiveness and durability of heavy machinery. When it involves choosing the right undercarriage elements, there are several aspects to consider. One essential aspect is comprehending the specific requirements of the maker and the atmosphere in which it will certainly operate. Various applications might require different kinds of undercarriage parts, such as tracks, rollers, sprockets, and idlers. It is vital to choose parts that are made to endure the specific problems the device will certainly come across, whether it be harsh surface, abrasive products, or extreme temperatures.Furthermore, considering the top quality and online reputation of the supplier is essential. Choosing trusted brand names recognized for creating durable and high-performance undercarriage parts can significantly affect the overall efficiency and durability of the machinery. Ensuring that the elements are suitable with the maker version and appropriately mounted is crucial for optimal efficiency. By carefully picking the best undercarriage components, tools owners can improve efficiency, reduce downtime, and prolong the life-span of their hefty machinery.

Situation Researches: Boosted Efficiency With Resilient Parts

Incorporating sturdy undercarriage components has demonstrated substantial improvements Read Full Article in machinery efficiency. One situation research study involved a building and construction firm that updated its excavator's undercarriage components to more durable options.In one more instance, a mining procedure changed the undercarriage parts of its bulldozer with high-quality, long lasting choices. This switch brought about a remarkable improvement in the excavator's ability to move and total efficiency. The device could browse challenging surfaces more efficiently, causing improved functional efficiency and lowered fuel usage.

In addition, a logging firm invested in sturdy undercarriage components for its forestry tools. The upgraded parts exhibited long term life expectancy and raised resistance to abrasion from harsh surface. Subsequently, the company experienced lowered upkeep expenses and enhanced tools uptime, ultimately increasing its bottom line. These instance research studies highlight the concrete benefits of utilizing resilient undercarriage components in maximizing equipment performance and long life.

Verdict

In verdict, making use of sturdy undercarriage parts can considerably enhance performance and longevity of hefty machinery. Elements such as appropriate upkeep and selecting the appropriate elements play a critical duty in taking full advantage of undercarriage toughness. By implementing these techniques, organizations can decrease downtime, rise efficiency, and ultimately save money on functional expenses. Situation studies have actually revealed that spending in sturdy undercarriage parts can result in enhanced general efficiency and productivity in various industries.The effectiveness and effectiveness of these parts can dramatically affect the overall procedure of machinery, making the choice of durable undercarriage parts an important choice for operators and managers alike.Integrating long lasting undercarriage components has actually shown substantial improvements in machinery performance. These case studies highlight the tangible benefits of utilizing long lasting undercarriage components in maximizing equipment efficiency and durability.

In verdict, making use of sturdy undercarriage components can significantly improve performance and longevity of hefty machinery (undercarriage parts). Case studies have revealed that spending This Site in long lasting undercarriage components can lead to boosted general performance and efficiency in various industries

Report this wiki page